- Specifications of Aircraft Grade Aluminum 7075(Aluminum alloy 7075)

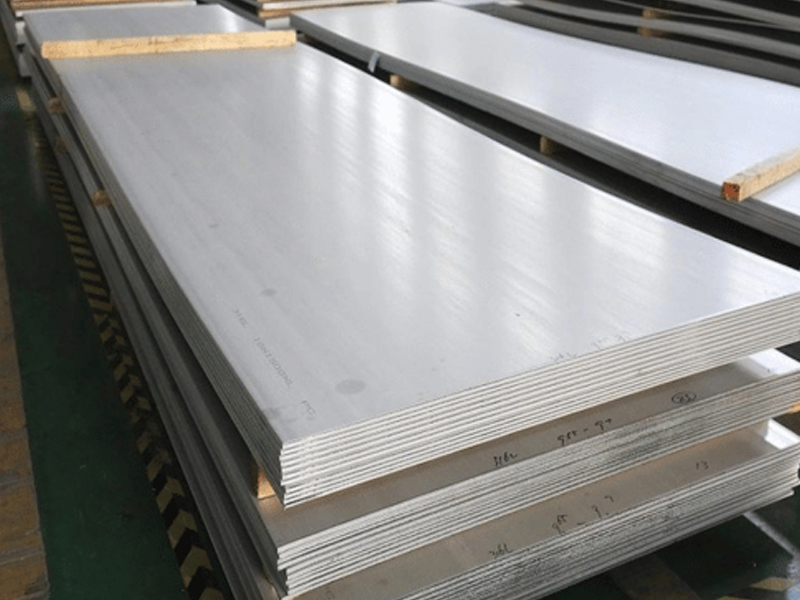

1. Type: Sheet/Plate, Coil, Tube, Extension, Parts

2. Grade:7075

2. Temper: T351

3. Thickness: 4-260 mm

4. Width: 1200-3800 mm

5. Standard: ASTM4124

6. Delivery Time: 15 – 30 Days

Key Advantages:

One-Stop Aluminum Fabrication Partner

110,000 Tons of Annual Production Capacity

15+ Years of Proven Expertise in Aluminum Products

Aluminum alloy 7075 Features

Highest Strength: Known as the strongest commonly used aluminum alloy, with strength comparable to many steels.

Lightweight & Machinable: Combines high strength with lightweight, easy machinability, making it ideal for aerospace and industrial uses.

Corrosion Resistance: Provides moderate corrosion resistance, with excellent stress corrosion resistance in T7351,T6 and T651 tempers.

Reflective Finish: Naturally reflective, polished finish reduces the need for painting and enhances visual appeal

Mechanical Properties

Tensile Strength 40-78 ksi, 275 - 540 MPa

Yield Strength 24-68 ksi, 455 - 465 MPa

Aluminium Alloy 7075 Physical Properties

Physical Properties Value Density 2.81 g/cm³ Melting Point 635 °C Thermal Expansion 240% IACS Modulus of Elasticity 72 GPa Thermal Conductivity 134 - 160 W/m.K

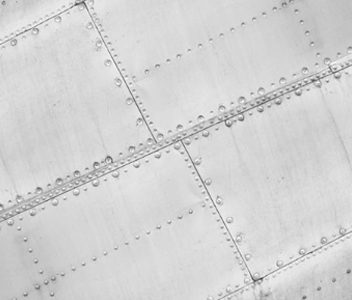

Aircraft Grade Aluminum 7075(Aluminum Aalloy 7075) is used in a wide range of aerospace

Landing Gears

Interior Conponents

Aircraft Wings

Aircraft Engines

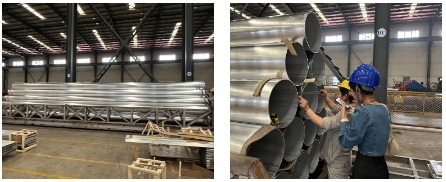

Our regular logistics work

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

Aluminum Alloy 7075 Aircraft Grade Aluminum 7075

Aircraft grade aluminum alloy 7075 has very high strength, used in aircraft wing structures and other highly stressed components, meets AMS 4045 and AMS 4124 standard. Moderate corrosion resistance and requires surface treatment.

Related Product

Choose A Series:

Post buying request

GLOBAL BUSINESS

Chat

Chat