- Specifications of Aviation Aluminum Alloy

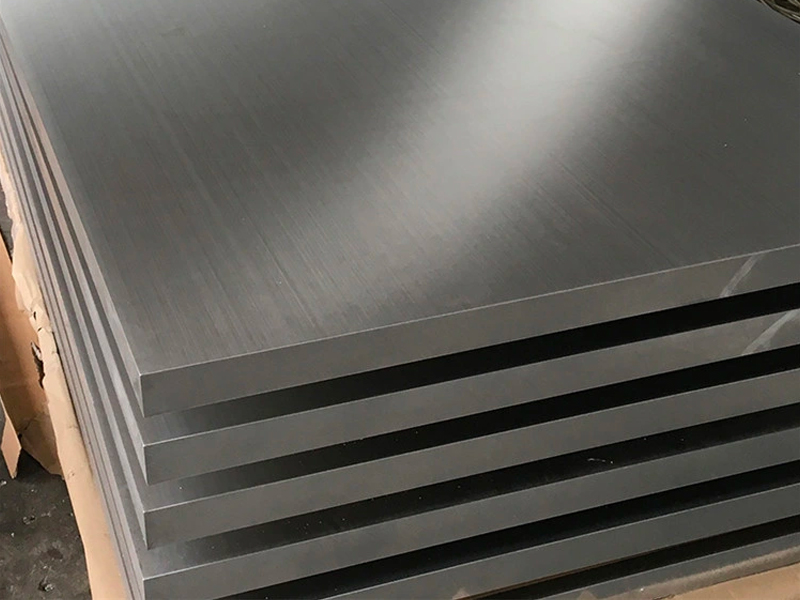

1. Type: Sheet/Plate, Coil, Tube, Extension, Parts

2. Grade: 2024-T351, 2124-T851, 6061-T651, 6063-T4/T651,6082-T651,

7050-T7451, 7075-T7351, 7075-T651, 7150-T651,7150-T7751,7475-T7351

3. Thickness: 4-260 mm

4. Width: 1200-3800 mm

5. Standard: AMS 4037, AMS 4027, AMS 4078

6. Delivery Time: 15 – 30 Days

Property Of Aircraft Aluminum Alloys

High Strength-To-Weight Ratio

Strong Corrosision Resistance

Thermal And Electrical Conductivity

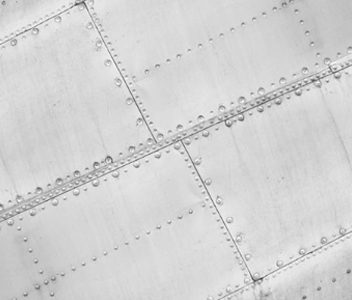

Aluminum alloys make up as much as 80% of materials used in most aircraft, thanks to their low density, high specific strength, excellent elasticity, outstanding ductility, and high corrosion resistance.

Aerospace Aluminum Alloys We Can Supply

The Grade Of Aircraft Aluminum That SM Aluminum Factory Can Supply.:

2xxx Series Aviation Aluminum Alloys

2xxx series alloys are mainly used where high damage tolerance and fracture toughness are essential features.

2024-T3 Aviation Aluminum

Grade 2024-T3 is the most common high-strength aluminum alloy. It is often considered aircraft quality. It has excellent fatigue resistance even though its corrosion resistance is lower than that of 6061. This aluminum alloy sheet is commonly used to make the fuselage, wing skins, aircraft structure, and cowls of most airplanes. It’s also ideal for repairs and restoration because it has a shiny finish.

We also can supply 2a12, 2024 T351, and 2017 T4/T451.

7xxx Series Aviation Aluminum Alloys

7xxx series alloys are widely applied in aerospace components where high strength is the driving requirement, including upper wing skins, horizontal and vertical stabilizers, and wing stringers.

7475-T7351 Aviation Aluminum

Aluminum-clad and unclad sheets for the fuselage. Other parts have both high strength and high fracture toughness, such as aircraft fuselage, wing skins, bulkheads, helicopter decks, landing gear doors, bullet casings, etc.

7075-T351 Aviation Aluminum

The primary role of this aluminum alloy is to strengthen aluminum aircraft structures. a careful mixture of copper, magnesium, and zinc made this alloy,to give it extra strength.However, because of copper, it is difficult but not impossible to weld. Once anodized, it has a beautiful finish and has the best machinability.

In addition to aircraft aluminum applications, spacecraft also use aluminum .Its unique properties are of even more value in this application.Up to 90% aluminum components made spacecraft. Space stations like the Skylab also use material and is expected to make even more appearances in manned space exploration.

7150 Aircraft Aluminum

High strength, Good corrosion resistance, Good toughness, Good workability, Good heat treatment rationality

7150-T7751 Aluminum extrusions: High tensile strength and hardness, low sensitivity to stress corrosion.

Application:Aircraft fuselage, wing beams, wings, and other aviation structural components.

7150-T76511 Aluminum extrusions: High strength, low sensitivity to stress corrosion, and good ductility.

Application:Aircraft structure, body structure, high-speed train and other fields.

Other Series Alloys

We can also provide other aviation aluminum alloys…

6061-T651 Aerospace Aluminum

This alloy has high corrosion resistance and finish. is easy to weld and has almost the same strength as mild steel. Mats in aircraft, truck bodies, and frames as well as structural components often use grade 6061-T6. It can be fabricated using the most common techniques which is an excellent property.

6063-T4 / T6 Aviation Aluminum

6063 aviation aluminum profiles have the characteristics of lightweight and high-strength, with a weight of about one-third of that of ordinary steel, but their strength is quite good, which can meet the needs of various loads.

5052-H32 Aviation Aluminum

5052-H32 is a non-heat treatable aluminum alloy and has one of the highest strengths in its class. It is not structural but has high fatigue strength compared to other alloys. It also possesses excellent corrosion resistance, particularly in marine applications. Its excellent workability makes this aluminum sheet ideal for the construction of fuel tanks.

3003-H14 Aviation Aluminum

This aluminum sheet has great workability and is one of the most widely used aluminum alloys. It is made from a blend of pure aluminum and manganese. This sheet is also non-heat treatable but can be deep drawn, welded, spun, or brazed. It’s perfect for making cowls in aircraft and baffle plating.

Grade Si Fe Cu Mn Mg Cr Ni Zn Al 2024 0.5 0.5 3.8-4.9 0.3-0.9 1.2-1.8 0.1 – 0.25 remaining 2124 0.2 0.3 3.8-4.9 0.3-0.9 1.2-1.8 0.1 – 0.25 remaining 6061 0.4-0.8 0.7 0.15-0.4 0.15 0.8-1.2 0.04-0.35 – 0.25 remaining 6063 0.2-0.6 0.35 0.1 0.1 0.45-0.9 0.1 – 0.1 remaining 6082 0.7-1.3 0.5 0.1 0.4-1.0 0.6-1.2 0.25 – 0.2 remaining 7075 0.4 0.5 1.2-2.0 0.3 2.1-2.9 0.18-0.28 – 5.1-5.1 remaining 7150 0.12 0.15 1.9-2.5 0.1 2.0-2.7 0.04 _ 6.1-7.50 remaining 7475 0.1 0.12 1.2-1.9 0.06 1.9-2.6 0.18-0.25 – 5.2-6.2 remaining

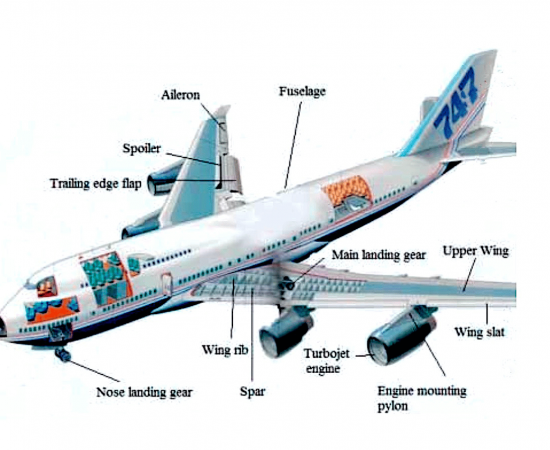

Real Applications Of Aerospace Aluminum

Real Applications Of Aerospace Aluminum

Unique properties of aluminum alloys make it an ideal material for various aircraft components, helping to improve both performance and safety. Let us find out where aluminum alloys are commonly used in aerospace industry

Landing Gears

Interior Conponents

Aircraft Wings

Aircraft Engines

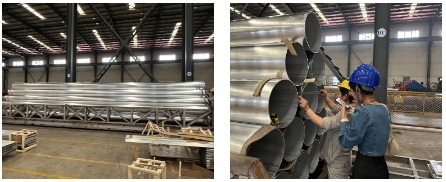

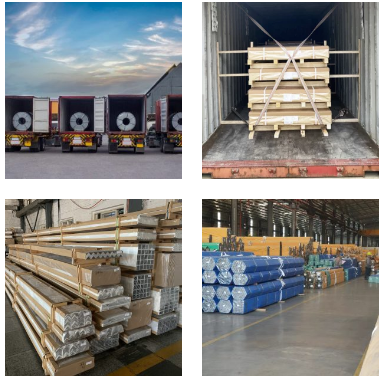

Our regular logistics work

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

Aviation Aluminum Alloy Aerospace Aluminum Alloys

As a professional aerospace aluminium alloys supplier , Shanghai Materials can offer 6061/6082/ 7050/7075/7475 aviation aluminum alloy with competitive price. Which widely used in lightweight aircraft ,spacecraft and aerospace industry. Most cruise missile casings are made of high-quality aluminum alloy castings and forgings. Currently, the structural consumption of aluminum in civil aircraft is 70%~80%, and the consumption in military aircraft structures is 40%~60%. In the latest B777 technology, aluminum alloy accounts for more than 70% of the airframe structural mass.Chinese Factory Wholesale Price.Over 20 years of industry experience, ISO 9001 certified. Precision 2024 aluminum plates with excellent yield strength & fatigue resistance. Ship out in 3-5 days. Professional Sales Team. Fast Quotation. 24 hours customer service.

Related Product

Choose A Series:

Post buying request

GLOBAL BUSINESS