- Specifications of 7150 Aircraft Aluminum/ 7150 Aluminum Alloy

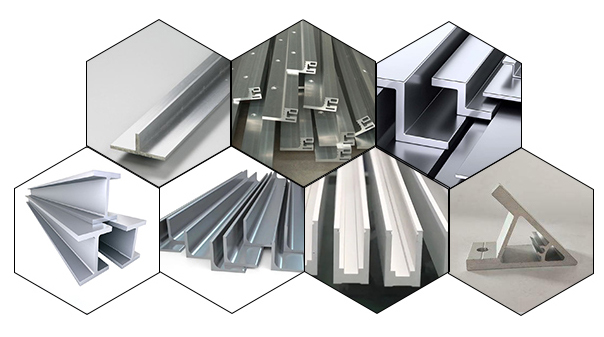

1. Type:Extension, Plate,Profile

2. Grade:7150

2. Temper:T651,T7751

3. Open Profile dimensions:Min 4mm*3mm, Max.850mm*50mm.

Closed profiles dimension:Min. 6.35mm*1mm, Max. 573mm*10mm.

4. Length: Maximum 28m(standard 6000mm)

5. Standard:AMS 4050 7150-T7751 Aluminum extrusions

AMS 4201 7150-T76511 Aluminum extrusions

AMS 4307 7150-T61511 Aluminum extrusions

AMS 4345 7150-T77511 Aluminum extrusions

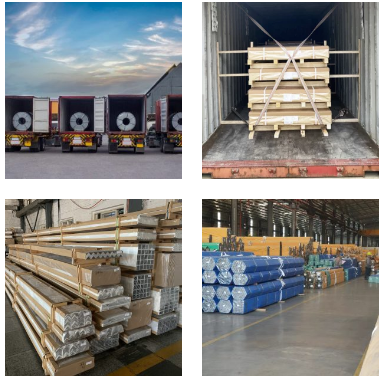

6. Delivery Time: 15 – 30 Days

Key Advantages:

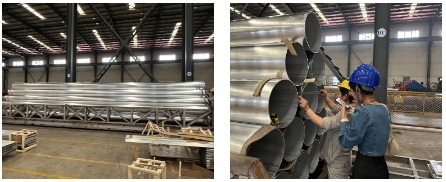

One-Stop Aluminum Fabrication Partner

110,000 Tons of Annual Production Capacity

15+ Years of Proven Expertise in Aluminum Products

7150 Aluminum alloy Features

High strength, Good corrosion resistance, Good toughness, Good workability, Good heat treatment rationality

7150-T7751 Aluminum extrusions: High tensile strength and hardness, low sensitivity to stress corrosion.

Application:Aircraft fuselage, wing beams, wings, and other aviation structural components.

7150-T76511 Aluminum extrusions: High strength, low sensitivity to stress corrosion, and good ductility.

Application:Aircraft structure, body structure, high-speed train and other fields.

Chemical composition of 7150 aluminum alloy

ElementComposition(%) Si 0.12 Fe 0.15 Cu 1.90-2.50 Mn 0.1 Mg 2.0-2.70 Cr 0.04 Ni - Zn 06.1-7.50 Ti 0.25 Al Remainder

Mechanical property of 7150 T77511 /T651 aluminum extrusion profile

Physical propertyAMS 4050 - 7150-T7751 AMS 4201 - 7150-T76511 AMS 4307 - 7150-T61511 Extrusion AMS 4345 - 7150-T77511 Extrusion Density 2.81 g/cm3 2.81 g/cm3 2.81 g/cm3 2.81 g/cm3 Tensile strength 560 MPa 540 MPa 550 MPa 560 MPa Yield strength 485 MPa 465 MPa 475 MPa 485 MPa Elongation rate 0.05 0.06 0.05 0.05 Impact toughness 33 J 31 J 30 J 32 J Brinell hardness 150 140 140 150

7150 Aircraft Aluminum is used in a wide range of aerospace

fuselage

wings

vertical tails

thrust reversers

other components

Our regular logistics work

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

If you are interested in our avation aluminum material , please submit the webform below with the informations . We will quote the latest aviation aluminum price to you within one business day . Customization and bulk orders are our specialty.

7150 Aircraft Aluminum 7150 Aluminum Alloy

7150 T651/T7751 aircraft aluminum meets the requirements of corrosion performance without sacrificing the strength of the aluminum alloy. which widely used in the aerospace industry for manufacturing aircraft fuselage, wings, vertical tails, thrust reversers and other components, as well as in missiles, satellites and other fields.

Choose A Series:

Post buying request

GLOBAL BUSINESS