- Specifications of copper foil/Rolled Copper Foil / RA Copper Foil

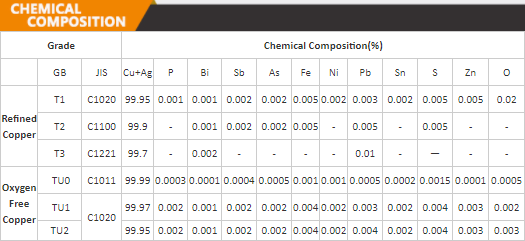

* Materials : 99.9% Pure copper foil

* Type:T2/TP2/TU1/TU2 C1100/C1220/C1011

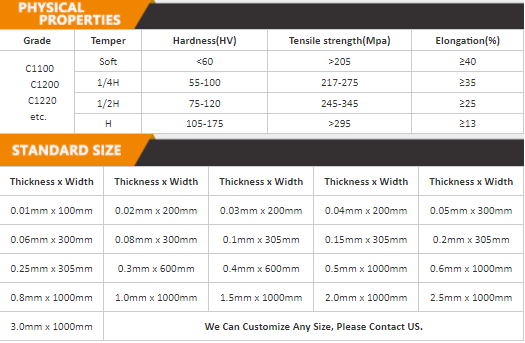

* Thickness:0.05-0.15mm

* Temper: M、Y4、Y2、Y

* Width: 5 – 620mm

* Length: as customized requirements

* Conductivity at 20°C: C11000 >97% ,C12200 >80%, C1020 >97%

Advantages:

Excellent for circuit wiring and electrical engineering

High purity, low resistivity, and good conductivity.

Wide range of thicknesses and sizes available

Features of copper foil :

Good shape processability, high conductivity and shielding ability

Applications of Copper Foil/ Rolled Copper Foil / RA Copper Foil :

1) Bonding pieces of stained glass

2) Transformers

3) electrical applications

4) High thermal heat conductivity

5) Connectors

6) Lead frames

7) Cable

8) Conduits

9) Wires

10)Rivets

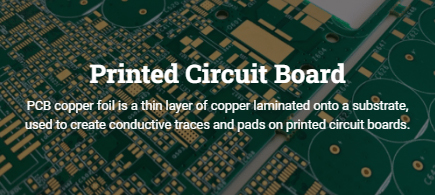

11)PCB field

About Us

There are 200 employees working in the factory. Among them, there are 42 technician, 3 engineer, and 40 logistics staff, and most of the other employees are experienced workers. With 20 years of manufacturing and processing copper material, we have induced developed manufacturing facilities to improve our quality

If you are interested in Copper/ Brass/ Bronze Products , please submit the webform below with the sizes . We will quote the latest price to you within one business day . Customization and bulk orders are our specialty.

Copper Foil Rolled Copper Foil / RA Copper Foil

We provide high temperature resistant copper foil its good shape processability, high conductivity and shielding ability. Which is ideal for simple grounding applications because it is very easy to weld. Double sided tin plating maximizes its resistance to external environmental impact and shielding ability. Application for conductive tape as conductive copper foil tape, motor EMI / RFI shielding as conductive copper foil tape,weldable heating elements, cable cabinet and components. The soldering of tin foil is very easy, which makes it very suitable for simple grounding applications.

Related Product

Choose A Series:

Post buying request

GLOBAL BUSINESS