Aluminum

Welcome to Shanghai Materials, a premier supplier of aluminum products in various forms, supporting industrial manufacturing. We specialize in aluminum coil, aluminum foil, aluminum sheets, aluminum tubes, aluminum bars, and more. Additionally, we provide value-added metal processing services with a can-do attitude. Our goal is to achieve complete customer satisfaction.

Choose A Series:

-

5005 Aluminum Sheet

5005 aluminum sheet / plate belongs to 5000 series aluminum magnesium alloy, but the magnesium content of the main alloy is lower than other 5000 series alloy plates, so its corrosion resistance is slightly higher than that of 3-Series alloy. Among them, the performance of 5005 aluminum alloy is similar to that of 3000 Series 3003 aluminum alloy, with moderate strength, good fusibility, good processability and formability, but its anodic oxidation effect is better than that of 3003 aluminum alloy, with brighter oxide film and the same color as 6063 aluminum alloy! Therefore, 5005 aluminum plate is commonly used in high-grade wide curtain wall panel, architectural decoration, automotive interior materials, instrument panel, oxidation materials, cookers, conductors and other aspects.

-

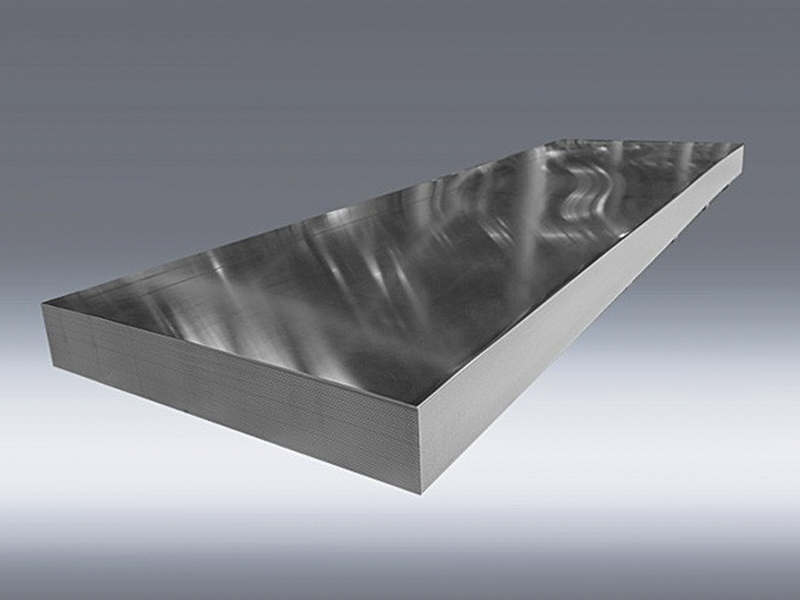

5052 ALUMINUM SHEET

5052 aluminum sheet belongs to 5000 series aluminum magnesium alloy. Magnesium is the main alloy element in 5052 aluminum, which improves its corrosion resistance and becomes the most widely used antirust aluminum. In addition, 5052 aluminum plate is also the most representative medium strength alloy. Although it is a medium strength alloy, it has high fatigue strength and better processability than 1000,3000 series alloys. At the same time, 5052 aluminum plate also has good weldability and formability. Based on so many characteristics, it is not difficult to find that the 3C products, doors, door handles, high-end building curtain wall panels around us all contain 5052 aluminum sheet/plate.

-

5083 H321 Aluminum Plate China

5083-h116 / H321 / h112 is a common tempering material.China Factory Wholesale Price.Over 20 years of industry experience, ISO 9001 certified. 5083 H321 Aluminum Plate has been successfully used in yachts, cruise ships and other hull. Through alloy composition determination, melting and casting process optimization, uniform heat treatment and rolling process test, the performance of 5083 aluminum plate can be compared with similar foreign products, which can meet the growing processing needs of complex parts such as marine aluminum plate, rail transit, automobile, mold and so on, and has broad application prospects.

-

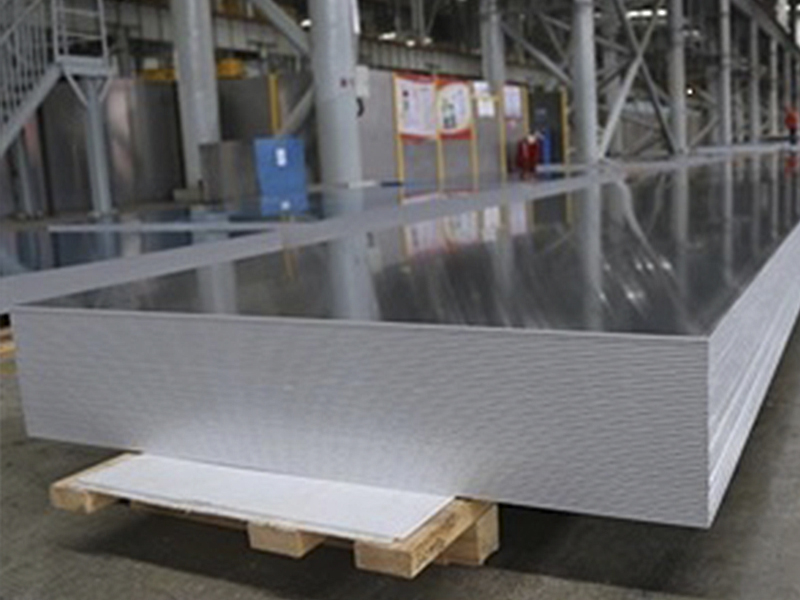

6061 ALUMINUM Plate

6061 aluminum plate is a high quality alloy product made by heat treatment and pre stretching. Although its strength can not be compared with 2000 series alloy or 7000 series alloy, 6061 aluminum alloy is mainly composed of Mg and Si, so 6061 aluminum plate has excellent processing performance, excellent weldability and electroplating performance, good corrosion resistance and high toughness. It is worth mentioning that the dense structure of 6061 aluminum plate does not deform after processing. In addition, 6061 aluminum alloy can be easily polished and colored, and its oxidation effect is also excellent. Knowing this, it is not difficult to find that 6061 aluminum plate is a suitable material for manufacturing precision machinery, automobile wheels, 3C products, mobile phone shell, mold, trolley case, alloy doors and windows.

-

ALUMINUM STRIP FOR LOUVER

Aluminum strip for louver is a common base material for cap sealing, such as aluminum alloy Ropp / screw / cap. Aluminum 3105 alloy shows good drawing, formability, corrosion resistance and good surface treatment effect! 3105 aluminum strip belongs to 3000 series of aluminum manganese antirust alloy. Its strength can be improved by cold treatment. In addition, due to the addition of manganese, the strength between the louver aluminum strip welds is improved, and the tendency of cracks is greatly reduced, showing good weldability. Therefore, 3105 aluminum strip is also widely used in lamp holder, shutter, sheet metal processing workpiece, color coated aluminum strip, top plate, corrugated plate, etc., among which 3105 H24 and 3105 H18 aluminum strips are commonly used.

-

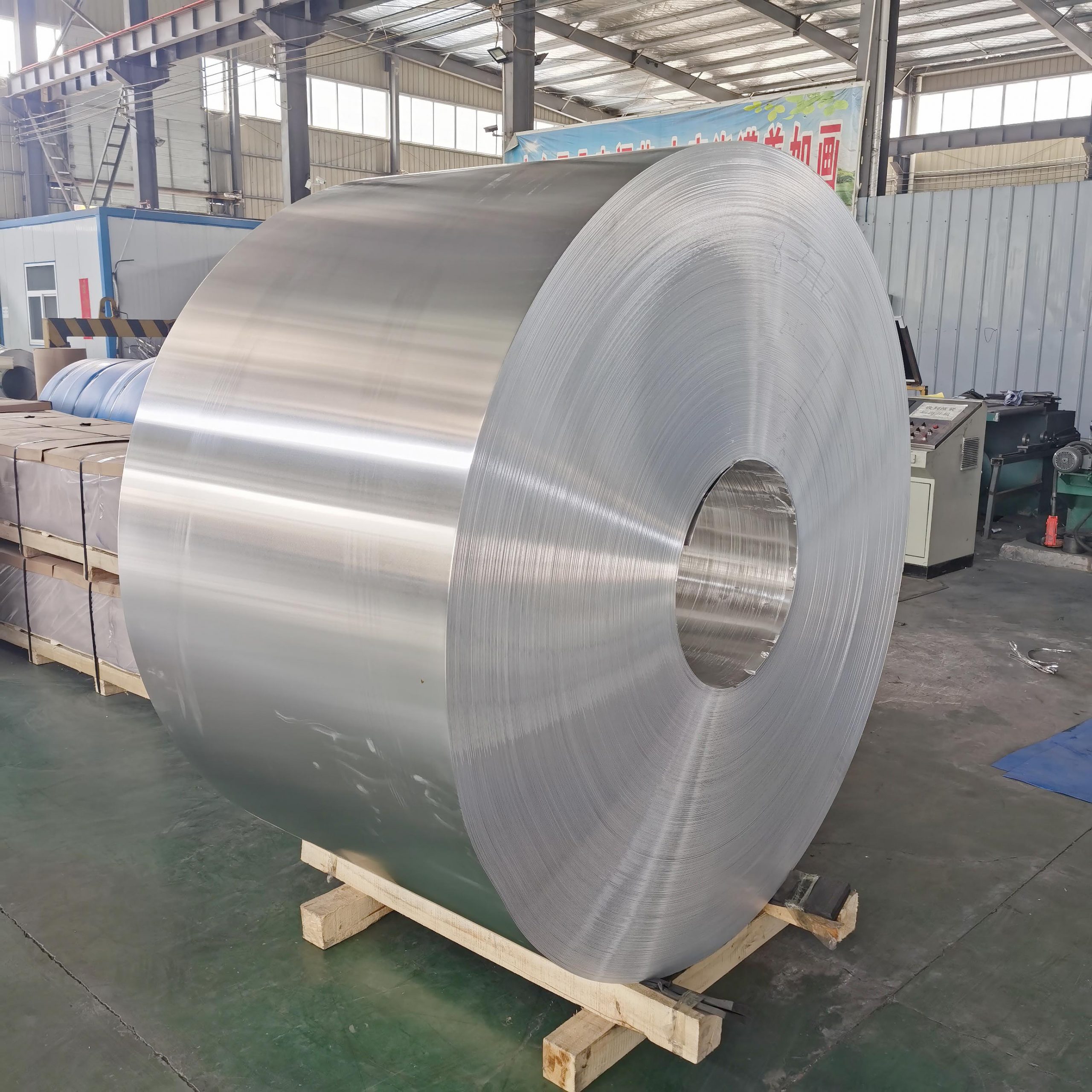

Aluminum Strip For Cable

Aluminum strip for cables belongs to the industrial pure forging 1000 series aluminum alloy series. The purity of aluminum is 99.5%. 1050 aluminum strip has good ductility, plasticity, corrosion resistance, high conductivity and thermal conductivity. In addition, 1050 aluminum alloy strip is also a non heat treated alloy with low strength, which cannot be strengthened by heat treatment and has weak workability. However, it can accept contact welding and gas welding. At present, due to its relatively simple production process, mature technology, and high economic efficiency, 1050 aluminum strip is very suitable for large-scale application in the industrial manufacturing field.

-

ALUMINUM STRIP FOR REFRIGERATOR

Aluminum strip for refrigerator has excellent conductivity, plasticity, thermal conductivity, elongation and other characteristics of pure aluminum. It is widely used in soft connection of power battery, capacitor shell, road sign, aluminum-plastic plate, lamp, building wall, etc. Here, the aluminum strip for refrigerator and freezer produced by our aluminum industry has mature technology, good quality and low price. It is suitable for polymer welding, refrigerator and freezer with high elongation, high tensile strength and good formability. It can fully meet the general processing requirements (such as stamping, stretching, etc.)

-

ALUMINUM STRIP FOR VENTILATION PIPE

Aluminum strip for ventilation pipe, with aluminum content of at least 99%, is the highest alloy content in 1000 series, so it has the strongest mechanical strength in this series. Similarly, 1100 aluminum strip also shows properties similar to those of other series of pure aluminum alloys. Such as excellent ductility, processability, corrosion resistance, weldability, surface treatment, conductivity and heat transfer. Due to its excellent processing performance, 1100 aluminum strip can be well adapted to the application and is difficult to form. Therefore, 1100 aluminum alloy coil is often used for large refrigerator aluminum lining, HVAC, aluminum clad plate, architectural decoration, deep stamping parts, sheet metal processing parts, nameplates, etc.

-

PTC COOLING STRIP ALUMINUM STRIP

PTC cooling strip is a high-quality aluminum alloy produced by heat treatment and pre stretching process, which has a series of advantages such as excellent processability, good weldability and so on. It enjoys a good reputation in the fields of mobile phone shell materials, automobile wheels, trolley case, 3C products, etc. We produce PTC cooling strip aluminum strip for many years, exquisite technology, advanced equipment, with price advantage, welcome to consult and purchase!

GLOBAL BUSINESS