Aluminum

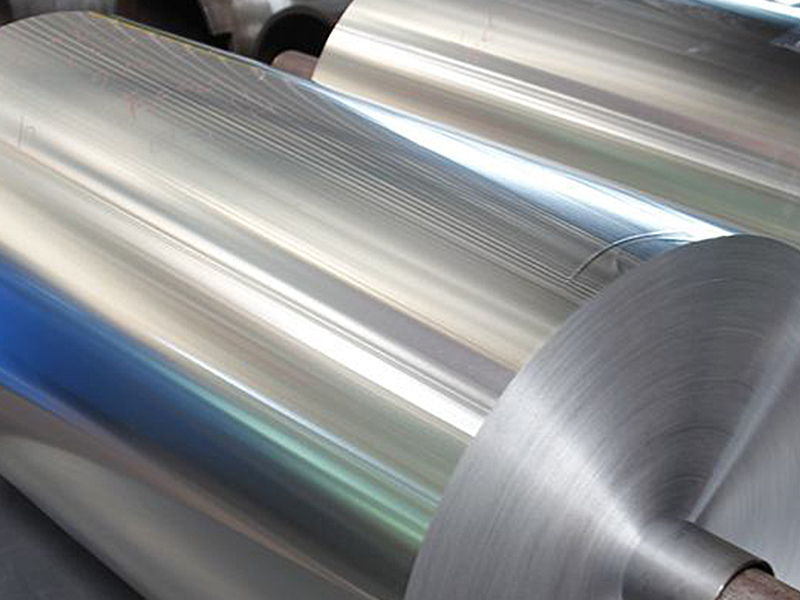

Welcome to Shanghai Materials, a premier supplier of aluminum products in various forms, supporting industrial manufacturing. We specialize in aluminum coil, aluminum foil, aluminum sheets, aluminum tubes, aluminum bars, and more. Additionally, we provide value-added metal processing services with a can-do attitude. Our goal is to achieve complete customer satisfaction.

Choose A Series:

-

1060 Aluminum Coil

High quality customized 1060 aluminum coil in different sizes.China Factory Wholesale Price.Over 20 years of industry experience, ISO 9001 certified.Aluminium 1060 coils commonly used in the electrical and chemical industries due to its high conductivity, corrosion resistance, and processability. Compared to metals with higher levels of alloying, 1060 aluminum has lower mechanical strength. It can be strengthened through cold processing, but not through heat treatment.

-

1100 Aluminum Coil

1100 aluminum coil has the strongest mechanical strength in the highest alloy in 1000 series. Which containing at least 99% aluminium . It shows the properties of other 1 series alloys close to pure aluminum. Such as excellent ductility, corrosion resistance, weldability, processability, surface treatment, conductivity and heat transfer. Because of its excellent processing performance, 1100 aluminum coil can be well adapted to the application and is difficult to form. Therefore, 1100 aluminum alloy coil is often used for large refrigerator aluminum lining, HVAC, aluminum composite panels, building decoration, deep stamping parts, nameplate, etc.

-

1350 Aluminum Alloy

1350 aluminum alloy containing 99.50% aluminium. The performance of 1350 aluminum alloy is similar to that of 1050 aluminum plate. However, the Si content in 1350 aluminum alloy is less than 0.10, which is lower than 0.25 Si in 1050 aluminum plate. In addition, 1350 aluminum alloy is also a non-heat treated alloy, which can be strengthened by cold working. To sum up, according to the characteristics of 1350 aluminum alloy, it is suitable for special products whose silicon content in the alloy must be lower than a certain value. In addition, it can also be used in the manufacturing fields of conductors, road signs, heat exchangers, aluminum awnings, beverage cans, cookers, wall coverings, etc.

-

3003 Aluminum Coil

3003 aluminum coil is a common aluminum manganese (Al-Mn) antirust alloy. It is also an alloy without heat treatment, and its mechanical properties can be improved by conventional cold working. In addition, due to its good corrosion resistance, excellent weldability, formability and other advantages, aluminum coil is often used in packaging, mechanical parts, refrigerators, air conditioning ventilation pipes, or ships, vehicles, pressure vessels, etc. Our aluminium products have smooth surface, small thickness tolerance and good stamping oxidation effect. After testing, the indicators are far beyond the standard indicators, products are guaranteed!

-

5005 Aluminum Coil

5005 Aluminum Coil Chinese Factory Wholesale Price.Over 20 years of industry experience, ISO 9001 certified. Aluminum alloy 5005 nominally contains 0.8% magnesium . It has medium strength,good weldability and good corrosion resistance in marine atmospheres.

-

5083 Aluminum Coil

5083 aluminum coil belongs to aluminum magnesium (Al-Mg) alloy ,which is the strongest corrosion resistant alloy in practical non-heat-treatment alloy. It is widely used in welding structure. Due to its excellent corrosion resistance, 5083 aluminum coil is also used as marine grade aluminum. 5083 is commonly used in surrounding cars, subway light rail, aircraft, pressure tank cars, TV Tower and other structural components. Our 5083 aluminum coil has smoother, finer surface, smaller thickness tolerance and better stamping oxidation effect. Through the test, all indicators are far beyond the standard indicators.

-

5154 Aluminum Coil

5154 aluminum coil is widely used in pressure vessels, ships and other welded structures. It belongs to Al-Mg ( 5000 or 5xxx series ) anti-rust alloy series and similar to 3A21 aluminum alloy, but the strength of 5154 with moderate-to-high strength, is higher than 3A21 and 5052 aluminum alloy, especially has higher fatigue strength, as well as high plasticity. 5154 aluminum coil is non-heat-treated alloy, can be cold worked to improve the mechanical properties.

-

5182 Aluminum Coil

5182 Aluminum Coil Chinese Factory Wholesale Price.Over 20 years of industry experience, ISO 9001 certified. 5182 aluminium alloy is one of the strongest non-heat treatable aluminum alloys. It is nominally a 4.5% magnesium alloy and its strength is further increased by an addition of approximately 0.3% manganese. 5182 aluminum coil can be effectively used in automobile and ship stamping parts, fuel tank / pipe, street lamp bracket, electronic shell, refrigeration device, oxygen generator, etc.

-

6061 Aluminum Coil

The 6061 aluminum coil has advantages such as excellent processing performance and good weldability. Which is a high quality aluminum alloy produced by heat treatment prestretching process, In mobile phone case materials, 3C products, automobile wheels, trolley cases, and other fields, enjoy a good reputation. Our aluminum production 6061 aluminum coil for many years, skilled technology, advanced equipment, has the price advantage, welcome to consult and buy!

GLOBAL BUSINESS