- Specifications of Electrical Grade Aluminum Bus Bar / Aluminum Busbar

* Diameter: 3mm –850mm

* Length: up to 24000mm

* Grade: 1xxx/2xxx/3xxx/5xxx/6xxx/7xxx

* Payment Terms : L/C acceptable

Technical Information of Aluminum Busbar:

Mechanical Properties of Aluminum Bus Conductor and Related Alloys

(The Aluminum Association ; ASTM B 236, B 241, and B 429; and Manufacturer’s Listings)

Product Alloy and Temper Thickness in Tensile Strength (ksi) Typical Typical Yield Typical(a) Ultimates At 20 (68。F) Ultimate Elongation (Percent – in 2 in. Extruded rod, bar tube, 1350-H111 All 8.5 3.5 35 pipe and shapes 6101-T6 0.125-0.500 29 25 32 28 15 6101-T61 0.125-0.749 20 15 0.750-1.499 18 11 1.500-2.000 15 8 6101-T63 0.125-0.500 27 22 14 11 6101-H111 0.250-2.000 12 8 6101-T64 0.125-1.000 15 8 6101-T65 0.125-0.749 25 20 Extruded pipe(c) 6061-T6 Pipe size 1.0 & 38 35 45 40 10.0 min 6063-T6 over Pipe sizes,all 30 25 35 31 8.0 min Rolled bar 1350-H12 0.125-1.000 12 8 14 12 Sawed-plate bar or sheet 1350-H112 0.125-0.499 11 6 10.0min 0.500-1.000 10 4 16.0min 1.001-3.000 9 3.5 22.0min Rolled sheet 1350 0.020-0.249 8 12 4 20-30 min (for shearing or forming) 1350-H12 12 14 12 4-9 min 1350-H14 14 16 14 3-6 min 1350-H16 0.020-0.125 16 18 16 2-4 min 1350-H18 18 2-4 min Cast Alloy for Bus 1350-F 1 in. And up 8.5 3.5 35 1050 Cast Alloy for Fittings A356.0-T61 37 5

Features of Electrical Grade Aluminum Bus Bar / Aluminum Busbar

1) Light-weight

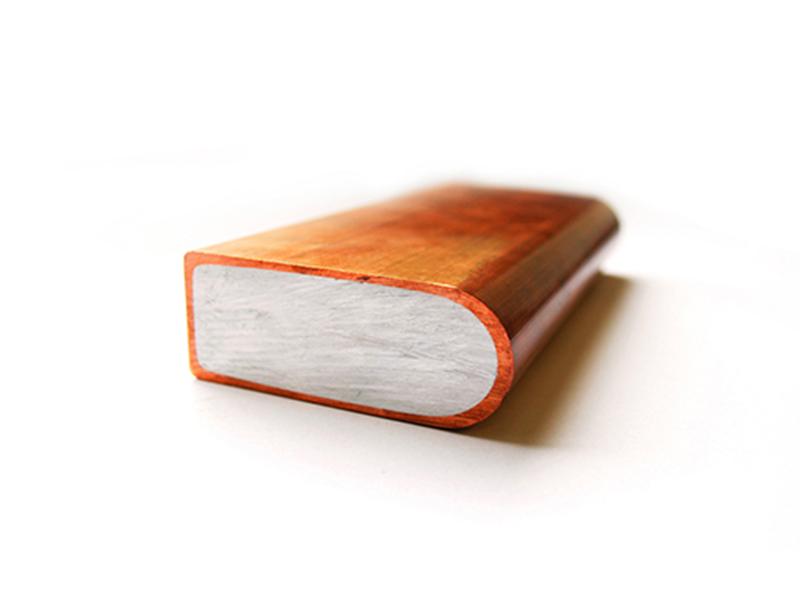

2) Strong combination of copper and aluminum

3) Strong Conductivity

4) Good ductility

5) Good corrosion resistance

If you are interested in our Aluminum Products , please submit the webform below with the sizes . We will quote the latest price to you within one business day . Customization and bulk orders are our specialty.

Electrical Grade Aluminum Bus Bar Aluminum Busbar

Electrical grade aluminum bus bar involves aluminum busbars, copper busbars, copper clad aluminum busbars. Hot products of aluminum busbar include 1050, 1060, 1070, 1100, 1350, 6061, 6101,6063, 6082... Whih widely used in electrical conductors of distribution systems.

Related Product

Choose A Series:

Post buying request

GLOBAL BUSINESS