- Specifications of Anodized Aluminum Sheet

1) Thickness: 0.3-5mm

2) Width: up to 2000mm

3) Anodic layer: 2-25µm

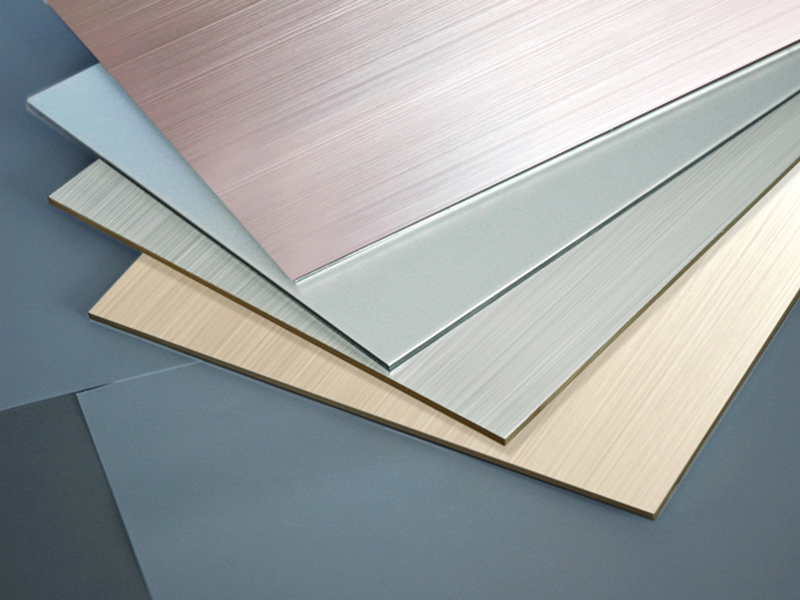

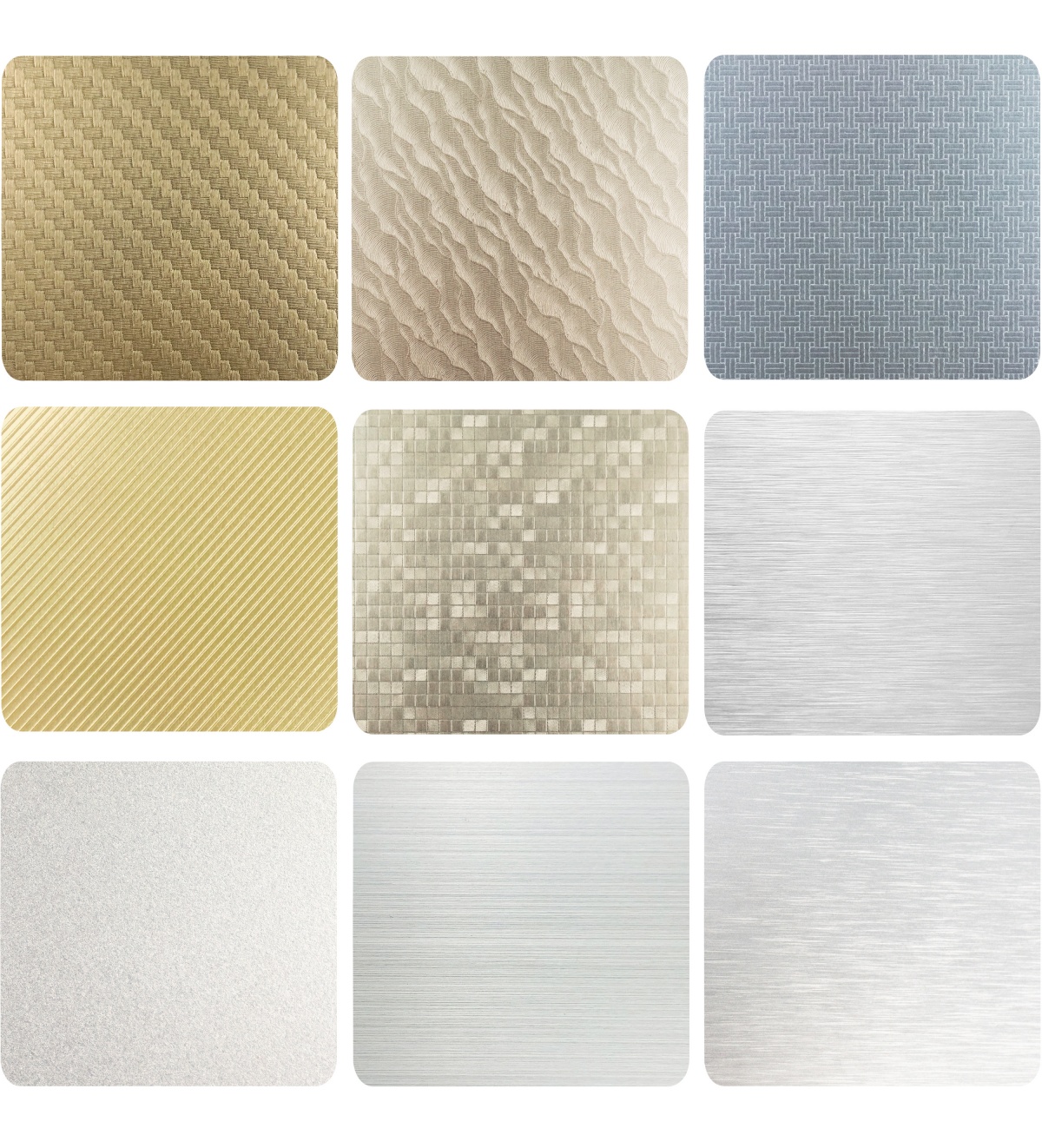

4) Colours:natural,Grey-Black,Gold,Bronze,Blue,Red,Stainless Steel

Features of Anodized Aluminum Sheets

1) Light weight, 1/3 weight of stainless steel

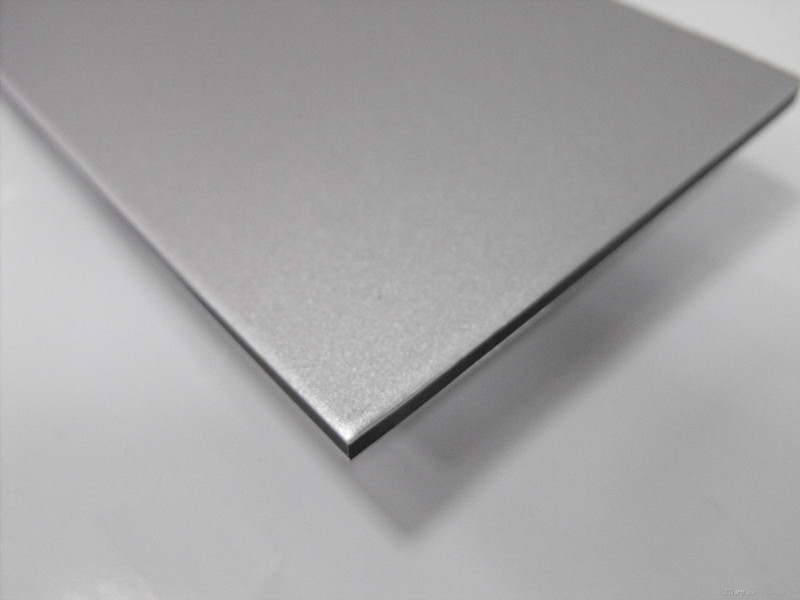

2) Anti-scratch, the surface hardness reaches Sapphire Grade

3) Non-poisonous and environmental protection

4) Anti-static, anti-fingerprint, easy to clean

5) The surface anodized layer will never fade or fall off

Applications of Anodized Aluminum Sheet:

1) Lighting

2) Inside and outside curtain wall

3) Automotive body

4) Home appliance board

5) Electrical Products

If you are interested in our Aluminum Sheet / Plate , please submit the webform below with the sizes . We will quote the latest price to you within one business day . Customization and bulk orders are our specialty.

Anodized Aluminum Sheet Anodised Aluminium Sheet

Anodized aluminum sheet is oxidized and a thin layer of alumina is formed on the surface, with a thickness of 5 ~ 20 μ m. The hard anodic oxide film is 60 ~ 200 μ m。 Anodized aluminum plate improves the hardness and wear resistance, up to 250-500 kg / mm2, good heat resistance, hard anodized film hardness up to 2320k, good insulation, breakdown voltage up to 2000V, and enhanced corrosion resistance ω= No corrosion for thousands of hours in salt spray of 0.03 NaCl. The oxide film has a large number of micropores in the thin layer, which can adsorb various lubricants. It is suitable for manufacturing engine cylinders or other wear-resistant parts; The microporous adsorption capacity of the membrane can be colored into various beautiful colors. Non ferrous metals or their alloys (such as aluminum, magnesium and their alloys) can be anodized.

Related Product

Choose A Series:

Post buying request

GLOBAL BUSINESS